Line defects or dislocations are a frequently observed phenomenon and represent a deviation from the strict atomic order of the crystal lattice. These defects influence the mechanical, electrical and optical properties of crystals as well as their growth behavior. For the development of high-quality crystals, it is therefore important to understand the origin and control the densities of dislocations. Although it depends on the specific application, dislocations have a detrimental effect on the crystals properties in most cases.

Once a dislocation is formed in the crystal, it cannot simply end, but will spread until it reaches the surface. Given sufficient temperature, however, dislocations can move due to internal stresses. This movement cannot take place in arbitrary directions but follows fundamental crystallographic rules based on different atomic mechanisms, denoted as glide or climb. Influencing this movement is thus one way to reduce the dislocation density in a crystal.

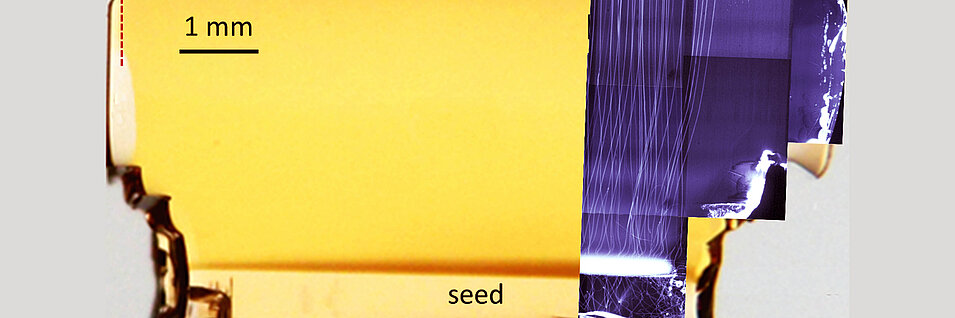

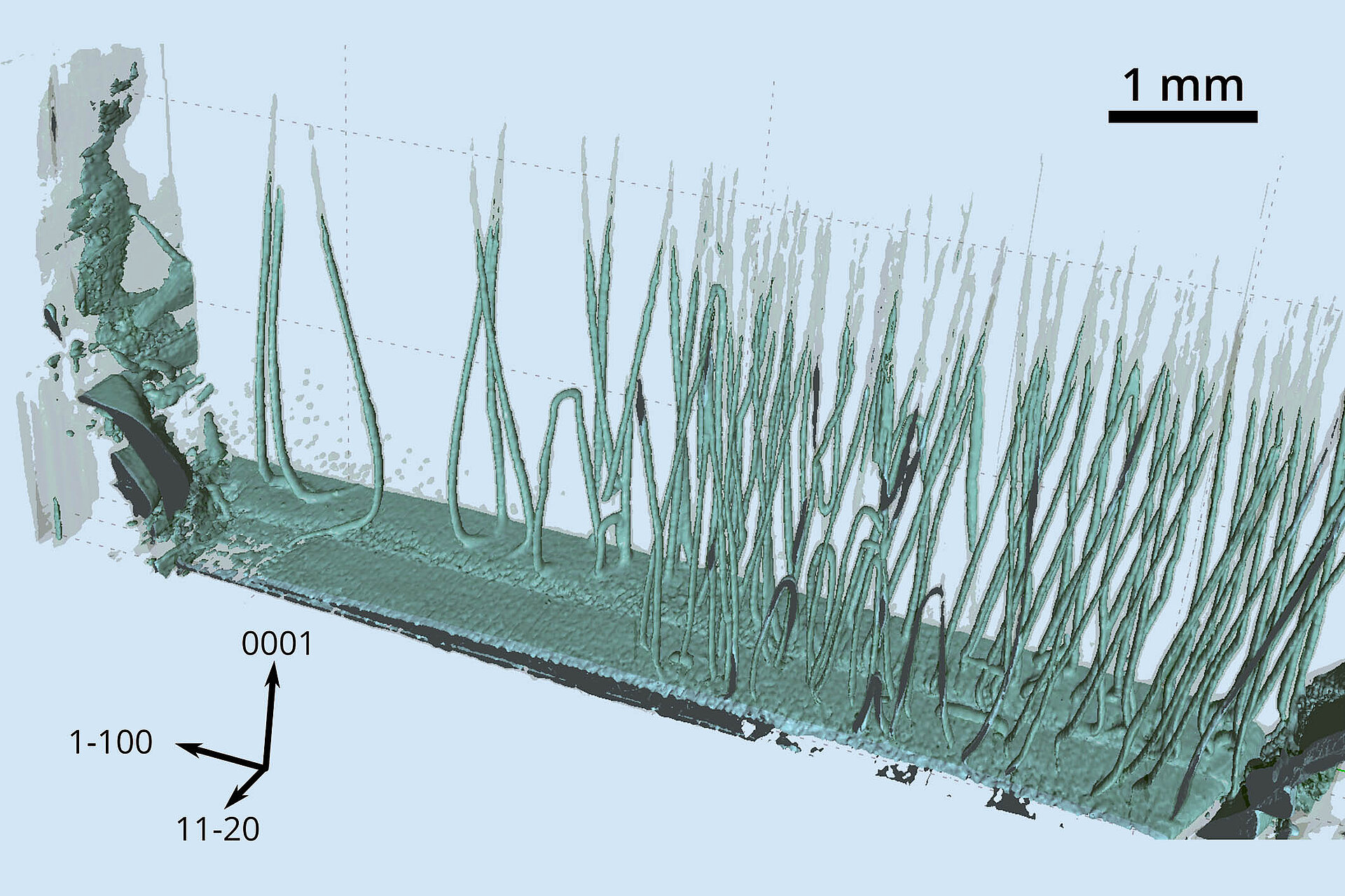

Three-dimensional (3D) imaging of the dislocation lines can provide valuable insight into the mechanisms of dislocation creation and their movement during growth. This way, scientist have indirect access to studying stress or impurity levels in the crystals and their shape as present during growth. This has been successfully demonstrated in a recent paper published by scientists from IKZ and Karlsruhe Institute of Technology [1]. Using 3D X-ray diffraction imaging they were able to recover the line shape and Burgers vectors of the dislocations in a aluminum nitride (AlN) single crystal obtained by seeded physical vaport transport growth at IKZ (Fig. 1).

The method, also called X-ray diffraction laminography (XDL), requires an intense, parallel as well as monochromatic X‑ray beam that is only available at synchrotron radiation sources (in this case PETRA-III, Hamburg). Highly precise mechanics are furthermore needed, to rotate the crystal about a specific reciprocal lattice vector (Fig. 2). Only this way, 3D information is accessible and a reconstruction of the illuminated volume is possible.