Section Semiconductors

Section Semiconductors

Mission

As one of the world leading research teams in semiconductor bulk single crystals, we are focusing on cutting-edge topics for key enabling technologies such as quantum computing, power electronics, silicon photonics, besides persistently working on the growth of conventional semiconductors of group IV and III-Vs. We are also increasing our capabilities by developing 8-inch dia Float Zone system for silicon (Si), and by utilizing our KristMAG® technology in Vertical Gradient Freeze (VGF) and Czochralski (Cz) techniques. We are providing crystals with custom properties to academic institutions for collaborations or as a service and further working closely with our industrial partners for production efficiency.

Research activities

On the success of 28Si kilogram prototype project, we are positioning as a valuable contributor to the international joint research projects like ultra-high pure germanium for neutrinoless double-beta decay detection, Si-Fibers and Si-mirrors to Einstein telescope for gravitational waves detection. We produce isotopically enriched and ultrahigh purity, high crystalline perfection Si single crystals by Float Zone method and its related crucible-free growth processes. We also devote the process development and optimization of VGF and Cz growth technology for III-Vs and Si respectively, especially using non-stationary magnetic fields to control the undesirable impurities and defects. We prepare Germanium single crystals with high doping level as well.

Head of section

Topics

FZ-Si

Silicon single crystals with ultrahigh purity and crystalline perfection are crucial for demanding applications in power electronics, photonics or basic research. The Float-Zone (FZ) method is particularly suitable for the growth of such crystals. We aim to provide FZ know-how, growth processes and custom-made crystals needed for enabling technologies in trends as e-mobility, smart and renewable energy or for the emerging field of quantum computing.

Our activities include the further development of FZ and related crucible-free growth processes (Pedestal, Silicon Granular Crucible method). For our partners in science and industry, we provide dislocation-free crystals with very high resistivity (>10kΩcm) and purity or targeted doping, e.g. with B, P, Bi, Ga, Al, Sb, Au, N. Our FZ furnaces allow the growth of crystals with a diameter of a few mm up to 200 mm. A special focus lies on the growth of isotopically enriched 28Silicon crystals.

Lucas Vieira, Iryna Buchovska, Iason Tsiapkinis, Arved Wintzer, Kaspars Dadzis, Robert Menzel

Simulation of crucible-free growth of monocrystalline silicon fibres for mirror suspension in gravitational-wave detectors

Journal of Crystal Growth 629 (2024) 127549

DOI: 10.1016/j.jcrysgro.2023.127549

Kirils Surovovs, Maksims Surovovs, Andrejs Sabanskis, Jānis Virbulis, Kaspars Dadzis, Robert Menzel, Nikolay Abrosimov

Numerical simulation of species segregation and 2D distribution in the Floating Zone Silicon crystals

Crystals 12 (2022) 1718

DOI: 10.3390/cryst12121718

Hans-Joachim Rost, Iryna Buchovska, Kaspars Dadzis, Uta Juda, Michael Renner, Robert Menzel

Thermally stimulated dislocation generation in silicon crystals grown by the Float-Zone method

Journal of Crystal Growth 552 (2020) 125842

DOI: 10.1016/j.jcrysgro.2020.125842

M. Nicolai Lorenz-Meyer, Robert Menzel, Kaspars Dadzis, Angelina Nikiforova, Helge Riemann

Lumped parameter model for silicon crystal growth from granulate crucible

Crystal Research and Technology 55 (2020) 2000044

DOI: 10.1002/crat.202000044

Robert Menzel, Hans-Joachim Rost, Frank M. Kießling, Lamine Sylla

Float-zone growth of silicon crystals using large-area seeding

Journal of Crystal Growth 515 (2019) 32–36

DOI: 10.1016/j.jcrysgro.2019.02.061

Nikolay Abrosimov, Dmitri Aref’ev, Peter Becker, Harald Bettin, Alexander Bulanov, Mikhail Churbanov, Sergei Filimonov, Vladimir Gavva, Oleg Godisov, Alexey Gusev, Tatiana Kotereva, Daniel Nietzold, Michael Peters, Alexander Potapov, Hans-Joachim Pohl, Andreas Pramann, Helge Riemann, Philipp-Tido Scheel, Rudolf Stosch, Stefan Wundrack, Stefan Zakel

A new generation of 99.999% enriched 28Si single crystals for the determination of Avogadro’s constant

Metrologia 54 (2017) 599–609

DOI: 10.1088/1681-7575/aa7a62

Silicon single crystal with a diameter of 4 inches, grown by the FZ method

Cz-IV

The Czochralski (Cz) group specializes in the growth of group-IV semiconductor crystals, silicon (Si), germanium (Ge) and their related alloys for a wide range of applications in electronics, photonics, plasmonics, thermoelectrics and efficient x-ray and γ-ray monochromators. As a member of the grand international GERDA/LEGEND collaboration, we are also striving to produce ultra-high purity Ge single crystals to be used as radiation detectors in astrophysics studies, in the quest for fundamental understanding of the universe. The focus lies in developing and establishing the whole value-chain process technology under one roof.

- Single crystal growth of ultra-high-purity Ge (n < 1011 cm-3), including the reduction of natural GeO2, isotopically enriched 76GeO2 to Ge and zone-refining of Ge up to 12N

- Growth optimization of heavily-doped (n > 1018 cm-3) Ge crystals using novel gas-phase doping technique, for THz Plasmonics applications

- Si, Ge crystals specifically doped with exotic dopants like Magnesium or Bismuth for their carrier dynamic studies with Free-Electron-Lasers

- SiGe mosaic crystals and gradient crystals for synchrotron beam line optics; GeSn and SiGeSn crystals for photonics application

Aravind N. Subramanian, Merve P. Kabukcuoglu, Carsten Richter, Uta Juda, Robert Kernke, Florian Bärwolf, Elias Hamann, Marcus Zuber, Nikolay V. Abrosimov, and R. Radhakrishnan Sumathi

Growth of Boron-Doped Germanium Single Crystals by the Czochralski Method

Cryst. Growth Des. 25, (2025) 1075−1081

DOI: 10.1021/acs.cgd.4c01413

Aravind N. Subramanian, Carsten Richter, Alexander Gybin, Merve P. Kabukcuoglu, Elias Hamann, Marcus Zuber, Maximilian Oezkent, Christo Guguschev, Uta Juda, Thomas Schroeder, Nikolay V. Abrosimov, R. Radhakrishnan Sumathi, Kevin-P. Gradwohl

On the Czochralski growth of SixGe1−x crystals as substrates for strained Ge quantum well heterostructures

J. Appl. Phys. 137 (2025) 065704

DOI: 10.1063/5.0238533

Pradeep Chandra Palleti, Alexander Gybin, Sabine Bergmann, Uta Juda, Martin Albrecht, and R. Radhakrishnan Sumathi

Development and Morphological Analysis of the Zone Refining Process for High Purity Germanium

Materials Science in Semiconductor Processing, Volume 185, January 2025, 108924

DOI: 10.1016/j.mssp.2024.108924

Kevin-P. Gradwohl, Alexander Gybin, Christo Guguschev, Albert Kwasniewski, Mike Pietsch, Uta Juda, Carsten Richter, and R. Radhakrishnan Sumathi

Single crystalline high-purity germanium bars grown by the zone-refining technique

Journal of Crystal Growth, Volume 632, 15 April 2024, 127645

DOI: 10.1016/j.jcrysgro.2024.127645

Pradeep Chandra Palleti, Palvan Seyidov, Alexander Gybin, Mike Pietsch, Uta Juda, Andreas Fiedler, Klaus Irmscher, and R. Radhakrishnan Sumathi

Properties of a highly compensated high‐purity germanium

J Mater Sci: Mater Electron, Volume 35, article number 57, 4 January 2024

DOI: 10.1007/s10854-023-11814-8

R. Radhakrishnan Sumathi, Alexander Gybin, Kevin-P. Gradwohl, Pradeep C. Palleti, Mike Pietsch, Klaus Irmscher, Natasha Dropka, Uta Juda

Development of Large-Diameter and Very High Purity Ge Crystal Growth Technology for Devices

Crystal Research and Technology, Vol. 58 (2023) p. 2200286

DOI: 10.1002/crat.202200286

Aravind Subramanian, Nikolay Abrosimov, Alexander Gybin, Christo Guguschev, Uta Juda, Andreas Fiedler, Florian Bärwolf, Ioan Costina, Albert Kwasniewski, Andrea Dittmar, R. Radhakrishnan Sumathi

Investigation of Doping Processes to Achieve Highly Doped Czochralski Germanium Ingots

Journal of Electronic Materials, Vol. 52 (2023) p.5178.

DOI: 10.1007/s11664-023-10534-3

R. Radhakrishnan Sumathi, Nikolay Abrosimov, Kevin-P. Gradwohl, Matthias Czupalla, Jörg Fischer

Growth of heavily-doped Germanium single crystals for mid-Infrared Applications

Journal of Crystal Growth 535 (2020) 125490

DOI: 10.1016/j.jcrysgro.2020.125490

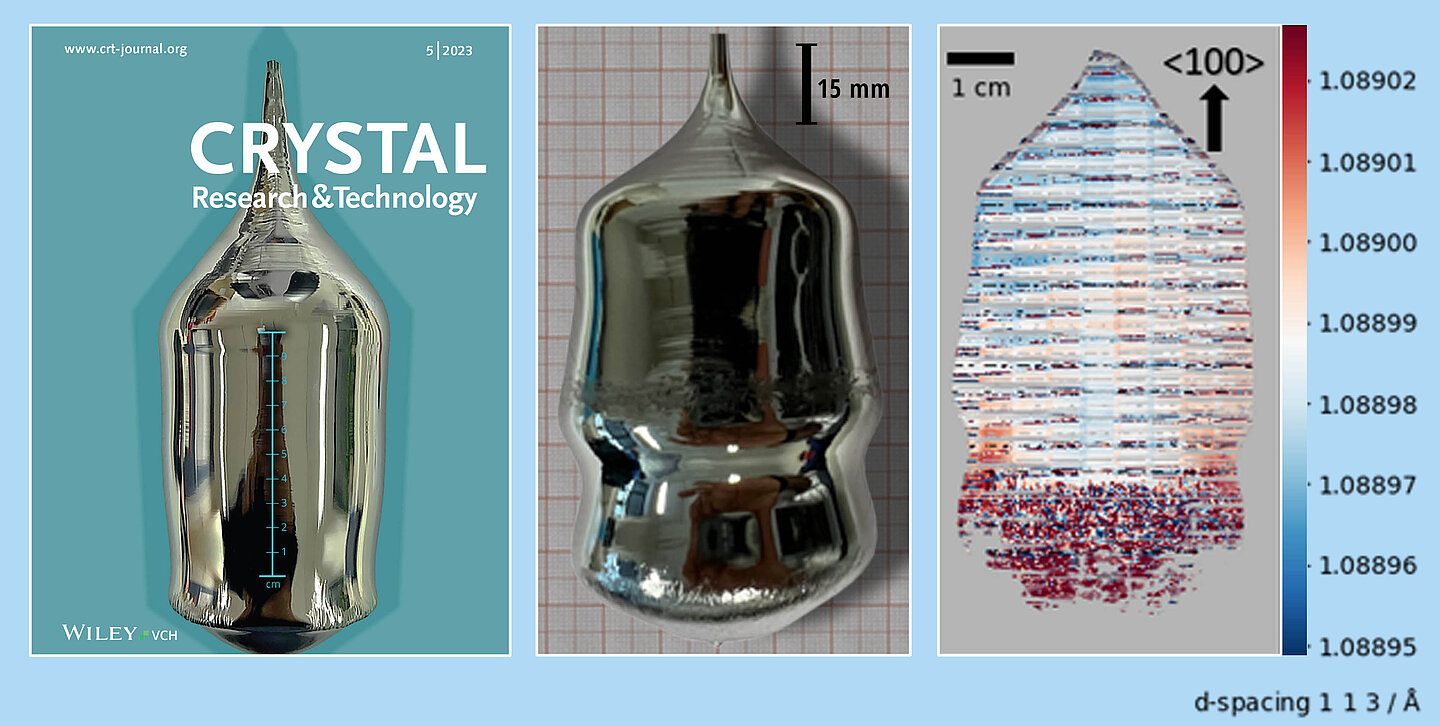

3-inch dia., 3 kg HPGe crystal grown at IKZ (left); Heavily Gallium-doped Ge crystal (C0=1018 cm⁻³) (middle); Rocking curve imaging (RCI) on a cross-section of a Ga-doped Ge crystal showing significant strain in the bottom part (i.e. in heavily doped region) (right).

VGF-III-V

Gallium Arsenide (GaAs) is beside Silicon (Si) the most commonly industrially used semiconductor material and is the one main focus of the group’s work. Research activities are centered on the improvement and optimization of the Vertical Gradient Freeze ( VGF) process with simultaneous application of magnetic fields, for example to improve process efficiency. A critical factor thereby is the precise and predictable control of fluid flow. A further central point of research is the VGF growth of III-V single crystals with specific characteristics for applications in basic research as well as special industrial applications such as detectors.

- Vertical Gradient Freeze (VGF) growth of III-V single crystals (ø = 4“) using KristMAG® heater-magnet-modules (HMM)

- Growth and characterization of III-V single crystals with custom specifications for research and industry

- VGF growth process development and optimization

- Realization of feasibility studies related to applications of KristMAG® technology

- Study of doping and impurity incorporation into crystals under the influence of external fields such as magnetic and ultrasonic fields

Christiane Frank-Rotsch, Natasha Dropka, Alexander Glacki, Uta Juda

VGF growth of GaAs utilizing heater-magnet module

Journal of Crystal Growth

DOI: 10.1016/j.jcrysgro.2013.12.063

Christiane Frank-Rotsch, Natasha Dropka, Peter Rotsch

III Arsenide

In Woodhead Publishing Series in Electronic and Optical Materials, Single Crystals of Electronic Materials,

Woodhead Publishing

DOI: 10.1016/B978-0-08-102096-8.00006-9

Christiane Frank‐Rotsch, Natasha Dropka, Frank‐Michael Kießling, Peter Rudolph

Semiconductor Crystal Growth under the Influence of Magnetic Fields

Crystal Research and Technology

DOI: 10.1002/crat.201900115

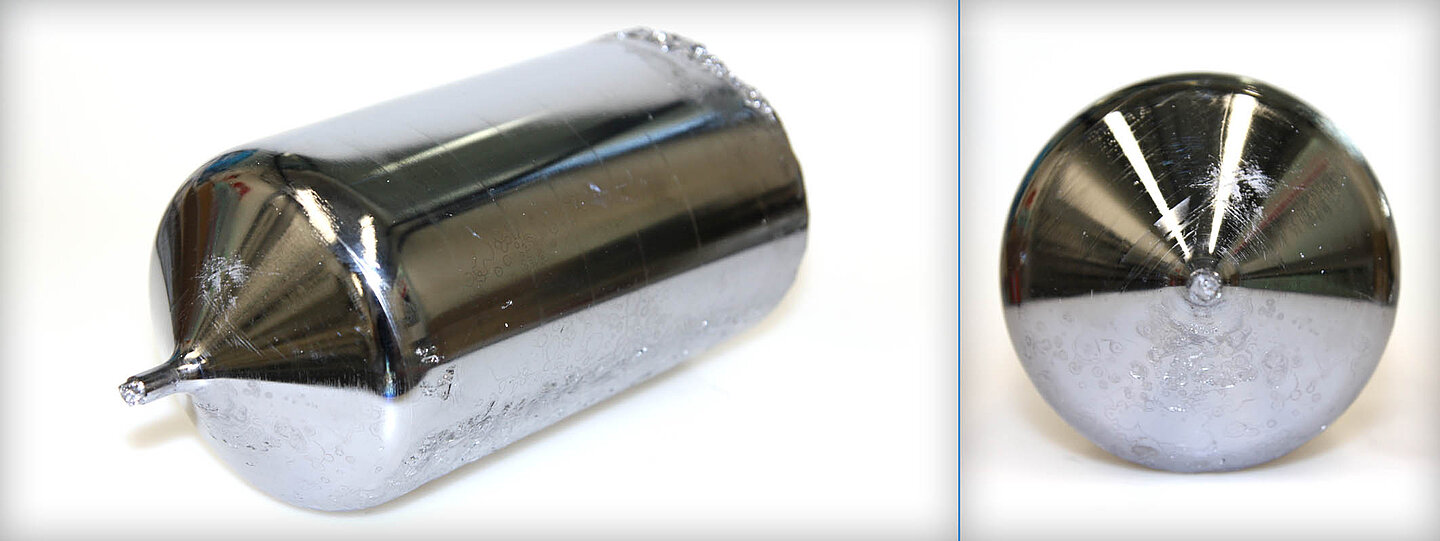

4" VGF GaAs crystal; Left: Side view; Right: View cone