Section Crystals for Electronics

Section Crystalline Materials for Electronics

Mission

Our aim is to produce small series of prototype substrates with tailored properties from semiconductor crystals with promising properties and to make these available to research partners to enable innovation in epitaxial and device processes or new applications. This requires not only the optimization of crystal growth and preparation processes with regard to technological capability, but also the development of standardized and efficient characterization methods for each specific material.

Research activities

For the key materials AlN and Ga2O3 with an extremely large band gap (ultra-wide band gap: UWBG), efficient and reproducible crystal growth and machining processes are to be developed for the production of prototype semiconductor substrates with diameters of up to 2” and beyond. The scientific focus is on structural defects and their avoidance as well as point defects (O, C, Si), which have a decisive influence on volume properties such as optical absorption and electrical conductivity.

The Micro-Structuring and Transfer working group aims to integrate these and other high-performance but expensive semiconductor materials as single-crystal µ-substrates into existing Si platforms.

The section also operates the “Crystal Machining” support lab.

Head of section

Topics

Aluminum Nitride Prototyping

Single-crystalline aluminium nitride is a promising substrate material for the production of ultraviolet light-emitting diodes (UV LEDs), which are used for disinfection, ultraviolet laser diodes (UV LDs), which are used for medical metrology applications and next-generation power electronics components. We produce AlN substrates with low dislocation densities, high UV transparency and high surface quality so that project partners can use them to develop new components.

Aluminium nitride (AlN) crystals are grown via physical vapor transport (PVT) in crucibles made of TaC or W and must have low dislocation densities and relevant diameters (>= 1") regardless of the planned application. Prerequisites for the production of AlN crystals with high crystalline quality are the availability of low-defect seeds, the avoidance of impurity precipitation during heating and an optimal T-field design (e.g. high T, low T gradients).

The increase in diameter is achieved by a gradual increase of seed diameters in several successive growth runs with suppression of parasitic growth and slow lateral growth by means of suitable lateral T-gradients. For use as a substrate for UV emitters, sufficient transparency is required in the desired wavelength range, which can be adjusted as required by specifically influencing the concentrations of the main impurities O, C and Si. Electrically conductive substrates for the production of vertical power electronics components are not yet available and the IKZ has set itself the goal of systematically investigating the underlying physical processes in order to realize n-conductive substrates technologically in case of success.

Carsten Hartmann, Merve Pinar Kabukcuoglu, Carsten Richter, Andrew Klump, Detlev Schulz, Uta Juda, Matthias Bickermann, Daniel Hänschke, Thomas Schröder, and Thomas Straubinger

Efficient diameter enlargement of bulk AlN single crystals with high structural quality

Applied Physics Express 16 (7), 075502 (2023)

DOI: 10.35848/1882-0786/ace60e

Thomas Straubinger, Carsten Hartmann, Merve P. Kabukcuoglu, Martin Albrecht, Matthias Bickermann, Andrew Klump, Simon Bode, Elias Hamann, Simon Haaga, Mathias Hurst, Thomas Schröder, Daniel Hänschke, and Carsten Richter

Dislocation Climb in AlN Crystals Grown at Low-Temperature Gradients Revealed by 3D X-ray Diffraction Imaging

Crystal Growth & Design 23 (3), 1538 (2023)

DOI: 10.1021/acs.cgd.2c01131

Andrew Klump, Carsten Hartmann, Matthias Bickermann, and Thomas Straubinger

Prediction of impurity concentrations in AlN single crystals by absorption at 230 nm using random forest regression

CrystEngComm 27 (2), 184 (2025)

DOI: 10.1039/d4ce00813h

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/5/c/csm_T_AlN_Kristallzuechtung_3118fb9092.jpg)

Left: Facilities for growing AlN single crystals at IKZ; Middle: View into the sublimation growth facility; Right: AlN single crystal

Gallium Oxide Prototyping

Single crystalline gallium oxide with its large band gap (4.5 - 4.8 eV) and high breakdown field (8 MV/cm) is a promising substrate material for the fabrication of efficient next generation power electronic devices. We produce low-defect gallium oxide substrates with 2” diameter, different orientations and defined off-cuts for project partners to develop new lateral (semi-insulating) or vertical (conductive) power electronic devices.

The central target of the group is to develop reproducible CZ crystal growth processes for the production of low-defect semi-insulating (Mg:) and conductive (Si:) gallium oxide crystals with diameters of at least 2” and lengths greater than 50 mm. This development is to be supported by basic research on structural defects (foreign grains, twin envelopes, dislocations) together with the Materials Science Department. In parallel, in-house machining processes are to be developed for the efficient and cost-effective production of 2” substrates. The focus here is on sawing the easily cleavable crystals with off-cut and producing the 100-X° and 010-X° substrate orientations.

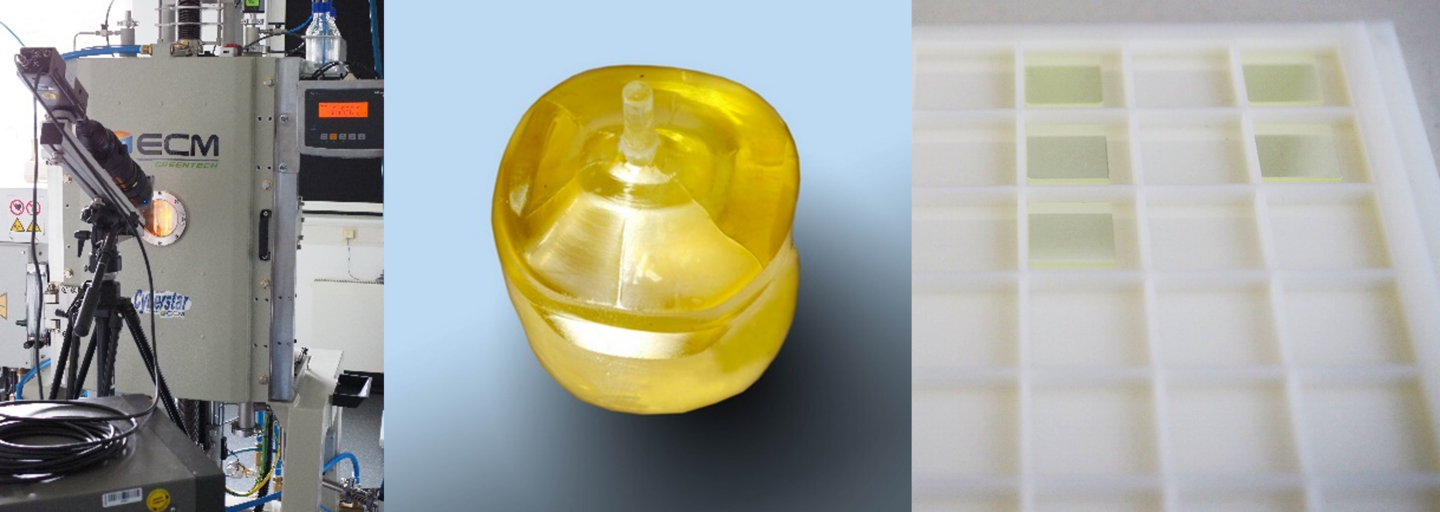

Left: CZ system for growing Ga₂O₃ single crystals at the IKZ; center: Mg-doped 2” Ga₂O₃ crystal; Right: Ga₂O₃ substrates

Micro-structuring & transfer

Semiconductor crystals of group III-V (e.g. InP, AlN) are substrate materials of the future for microelectronic, photonic, and opto-mechanical components that find applications in areas such as mobile communication, sensing, medical technology, and automotive. Integrating them into mature Si or sapphire-based technology platforms has the potential to realize cost-effective semiconductor devices with superior properties.

To enable this fundamentally new and future-oriented device generation, we want to develop preparation and transfer processes for integration on Si and other target substrates for III-V bulk crystals grown at the IKZ. Our activities are conducted in close collaboration with the bulk crystal growth (VGF-III-V, Aluminium Nitride Crystal Growth) and Wafering research groups, the IKZ-IRIS joint lab „Layer Transfer" as well as partners specialized in device development.

The R&D activities include:

- Preparation of InP and AlN single crystals with high crystalline perfection and tailored bulk properties (especially doping) into thin layers or micro-platelets with atomically smooth surfaces and low defect densities in preparation for the transfer.

- Optimization of the necessary chemical-mechanical polishing processes (surface) and lithography techniques (micro-structuring).

- Development of methods for characterizing the structural, optical, and electrical properties of the thin layers and micro-platelets.

- Development of transfer processes for the heterointegration of thin layers and micro-platelets onto Si substrates and other material platforms.

- Development of device demonstrators in collaboration with external project partners.

- Investigation of the influence of doping, micro-preparation, and bonding on crystal properties and device parameters.

- Adaptation and optimization of the developed methods for other application-relevant materials.

Isabella Peracchi, Carsten Richter, Tobias Schulz, Jens Martin, Albert Kwasniewski, Sebastian Kläger, Christiane Frank-Rotsch, Patrick Steglich, Karoline Stolze.

Preparation and Investigation of Micro-Transfer-Printable Single-Crystalline InP Coupons for Heterogeneous Integration of III-V on Si.

Crystals, 13 (7), 1126, 2023.

DOI: 10.3390/cryst13071126

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/f/5/csm_T_Mikro_Transfer_V1_00ada0087c.png)

Process chain – from single crystal to III-V on Si integration; Left: III-V single crystals, 1’’ AlN and 4’’ InP; Centre left: 10 µm thin InP-layer with AFM image; Centre right: InP micro-platelets; Right: Schematic image of transferred micro-platelets on Si target substrate.

Wafering

At the IKZ the installation of a technology-ready processing line for the preparation and characterization of semiconductor substrates with diameters up to 2" is planned. Currently, the IKZ is already able to produce demonstrator substrates (e.g. aluminium nitride) with small diameters and high quality. For the production of prototypes and small series, the machining effort must be reduced and the process reproducibility must be improved.

Central technical or scientific challenges in the production of semiconductor substrates are:

- Low-loss sawing of crystals with different mechanical properties, especially of brittle materials.

- Precise orientation of crystals or substrates.

- Realization of a high structural surface quality through optimal polishing processes.

- Realization of a high surface purity by avoiding contamination during the machining processes and suitable final cleaning processes.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/4/f/csm_T_Substratherstellung_f397b298a6.jpg)

Left: Wire sawing; Middle: Substrates on polishing carrier; Right: TEM images of an AlN substrate surface after chemical-mechanical polishing - Top: Crystal volume near the surface (dark) in low magnification - Below: Near-surface ordered atomic structure without damage in high resolution