Section Fundamental Description

Section Fundamental Description

Mission

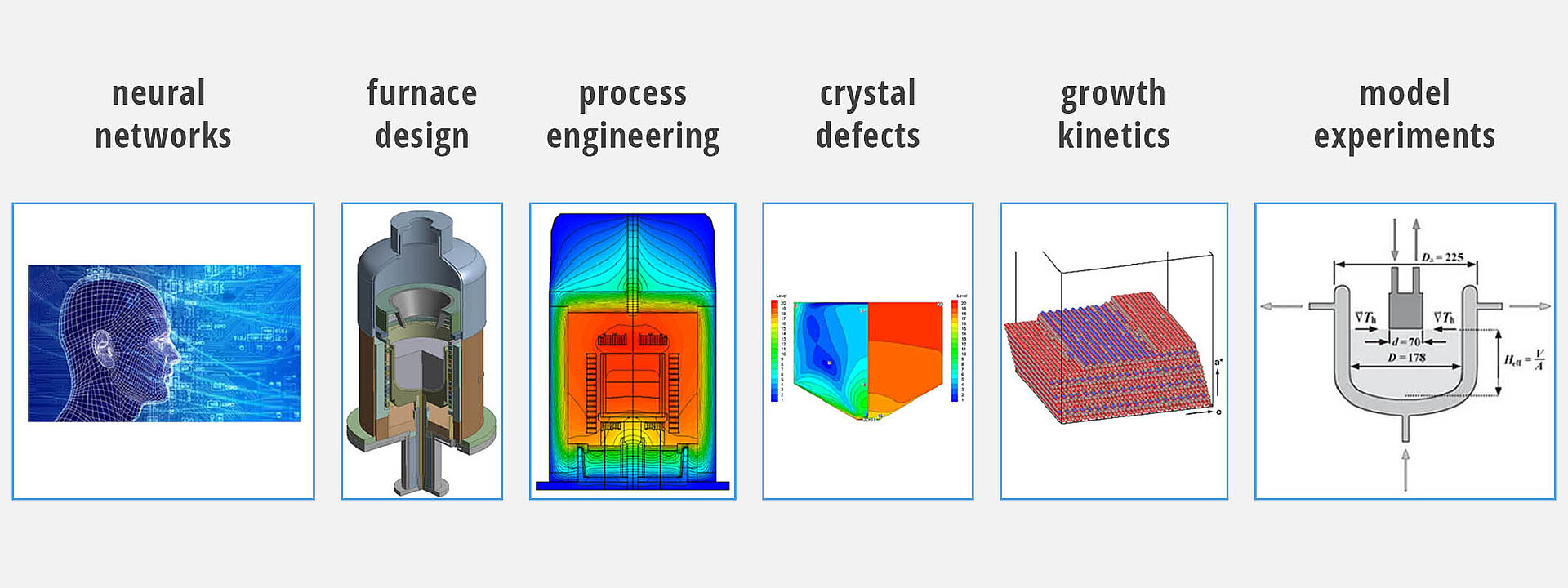

The section Fundamental Description has the aim to provide deeper insight into crystal growth processes by numerical simulations, covering topics from atomic level and basic research up to the applied science on the industrial scale, for both in-house and external partners. The physical understanding of the bulk crystal growth is supported by model experiments on the lab scale in the frame of ERC starting grant for young researchers.

Research activities

The research activities include: development and optimization of the crystal growth processes and furnace prototype designs on the various scales with multi-physics coupling. The validation of numeric models is supported by low temperatures model experiments. On the atomic level, simulation of crystal defects and growth kinetics are contributing to the understanding of the critical aspects of the crystal growth. Various applications of AI came recently into the focus.

Head of section

Topics

Junior Research Group "Model experiments"

Crystalline materials are produced in complex high-temperature processes involving a large variety of physical phenomena from heat transfer to fluid dynamics. We are working on a new generation of multiphysical models for these processes within the NEMOCRYS project funded by a Starting Grant from the European Research Council (ERC). The expected paradigm change in the way how we observe, describe and develop crystal growth processes will minimize the necessary experimental cycles and open new horizons for scientific analysis as well as for smart process control using artificial intelligence and other modern technologies.

We are developing a series of unique crystal growth setups for model materials to enable low working temperatures, relaxed vacuum-sealing requirements and hence an easy experimental access for various measurement techniques. The obtained in-situ measurement data are used to develop and validate multiphysical models, which are then applied for various crystal growth processes both on research and industrial scales. Furthermore, model experiments are employed to optimize the techniques for in-situ observation as well as to build a new basis for model benchmarking and for big data concepts in crystal growth.

Kaspars Dadzis, Olf Pätzold, Gunter Gerbeth

Model experiments for flow phenomena in crystal growth

Crystal Research & Technology, 55(2) (2019) 1900096

DOI: 10.1002/crat.201900096

Kaspars Dadzis, Paul Bönisch, Lamine Sylla, Thomas Richter

Validation, verification, and benchmarking of crystal growth simulations

Journal of Crystal Growth, 474 (2017) 171-177

DOI: 10.1016/j.jcrysgro.2016.12.091

Kaspars Dadzis, Gleb Lukin, Dagmar Meier, Paul Bönisch, Lamine Sylla, Olf Pätzold

Directional melting and solidification of gallium in a traveling magnetic field as a model experiment for silicon processes

Journal of Crystal Growth, 445 (2016) 90-100

DOI: 10.1016/j.jcrysgro.2016.03.037

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/a/b/csm_T_Modellexperimente_01_746d1330b2.jpg)

Crystal growth setups for the validation of multiphysical models

Artificial intelligence in crystal growth

Artificial intelligence (AI) based on artificial neural networks (ANN) can significantly reduce costs and shorten time for development of novel crystalline materials and crystal growth processes. The main reason for using ANNs is to quickly extract patterns and relationships in crystal growth data sets that are too complex to be noticed by other numerical techniques. The fast forecasting is crucial for the process control where in situ measurements of process parameters are not feasible.

The IKZ used static ANNs for parameter optimization in the magnetic driven growth of VGF-GaAs and DS-Si. A recent research topic was the application of dynamic neural networks for real-time prediction in the transient VGF-GaAs crystal growth process. For example, temperature distributions in the furnace as well as the position of the crystallization front during the growth can be quickly predicted. The AI application to other crystal growth topics is currently in progress.

Natasha Dropka, Martin Holena

Application of Artificial Neural Networks in Crystal Growth of Electronic and Opto-Electronic Materials

Crystals 10 (2020) 00663

DOI: 10.3390/cryst10080663

Natasha Dropka, Martin Holena, Stefan Ecklebe, Christiane Frank-Rotsch, Jan Winkler

Fast forecasting of VGF crystal growth process by dynamic neural networks

Journal of Crystal Growth 521(2019) 9-14

DOI: 10.1016/j.jcrysgro.2019.05.022

Natasha Dropka, Martin Holena

Optimization of magnetically driven directional solidification of silicon using artificial neural networks and Gaussian process models

Journal of Crystal Growth 471 (2017) 53-61

DOI: 10.1016/j.jcrysgro.2017.05.007

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/5/b/csm_T_AI_dbef7574e3.jpg)

Example of ANN architecture

Growth Kinetics

Crystal Growth is a kinetic process where atoms are integrated in a crystal lattice. This takes place for growth of bulk crystals and for deposition of crystalline layers. Understanding the kinetic processes is of great importance for the structure and the properties of the material as well as for the process engineering. Numerical calculations provide a deeper knowledge in concjunction with specific characterization methods such as e.g. transmission electron microscopy (TEM) or atomic force microscopy (AFM).

We develop a general kinetic Monte Carlo (KMC) tool using the programming language julia. The energy barriers for the various kinetic processes could be computed by potential models (Tersoff, ACE etc.) or via the bond counting method. They might be also taken directly from ab initio calculations for certain configuration.

This enables us to investigate the kinetics of different systems by atomistic computations using a unique framework. Currently, we investigate the epitaxial growth of AlN and AlGaN on AlN(0001), the homoepitaxy of Ga2O3 and the solution growth of Herbertsmithite.

Wolfram Miller, Tobias Schulz, Liverios Lymperakis, Andrew Klump, Martin Albrecht

Kinetic Monte Carlo simulations for AlN and AlGaN epitaxial growth on AlN

J.Crystal Growth 607 (2023), 127125

DOI: 10.1016/j.jcrysgro.2023.127125

Wolfram Miller, Dennis Meiling, Robert Schewski, Andreas Popp, Saud Bin Anooz, Martin Albrecht

A KMC model for homoepitaxial growth of Ga2O3

Phys. Rev. Research 2 (2020) 033170

DOI: 10.1103/PhysRevResearch.2.033170

Oleg Weinstein, Alexander Virozub, Wolfram Miller, Simon Brandon

Modeling anisotropic shape evolution during Czochralski growth of oxide single crystals

J. Crystal Growth 509 (2019)71-86

DOI: 10.1016/j.jcrysgro.2018.12.019

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/0/3/csm_T_Kinetik_fc64d7aaac.jpg)

Atomistic structure during layer growth computed by KMC; On top: step structure as obtained in TEM

Junior Research Group "Optimization and process control"

In the research group Optimization and process control we specialize in the innovative application of mathematical optimization (MO) and advanced artificial intelligence methods (AI) to control and enhance crystal growth processes. Our vision is to redefine the methodologies used in crystal growth through the integration of state-of-the-art MO and AI technologies. We aim to develop control strategies that significantly enhance the efficiency of the growth process and quality of crystals.

Our main objective is tosupport equipment and process design by advanced modelling techniques. Specifically, we aim to:

- Innovative Techniques: Develop cutting-edge techniques that integrate physics-informed models with machine learning.

- Enhance Process Control: Improve control over crystal growth processes through innovative MO and AI applications.

- Quality and Efficiency: Optimize the growth conditions to maximize quality and operational efficiency.

Our group aims to advance the field of material science by fostering the development of superior crystal growth technologies. This work supports various industrial applications, contributing to advancements in electronics and renewable energy sectors.

We invite academic and industrial collaborators to join us in pushing the boundaries of materials science through advanced research.

Advanced MO and AI Methods

Our research leverages sophisticated MO and AI to develop control systems that optimize the parameters influencing crystal growth. These methods enable us to simulate and predict crystal growth behaviors with high accuracy, leading to improved outcomes.

Simulation and Optimal Control

By applying optimal control theories and simulation tools, we enhance the precision with which crystal environments are managed. Our goal is to consistently produce high-quality crystals by fine-tuning the conditions under which they grow.

Hybrid Modeling

We focus on creating hybrid models that integrate empirical and simulation data with AI-driven insights. These models are critical in developing robust predictive tools for crystal growth processes, ensuring better control and optimization strategies.

Rössig, A., Petkovic, M. Advances in verification of ReLU neural networks. J Glob Optim81, 109–152 (2021).

https://doi.org/10.1007/s10898-020-00949-1

Le, T.T, Petkovic, M. Predicting Fluid Interface Instability in Energy Systems for Sustainable Energy Transition, to appear in Lecture Notes in Operations Research Operations Research Proceedings, 2023