Andrew began his career in the III-Nitrides as a secondary ion mass spectrometry analyst at EAGlabs, inc. before earning his Ph.D. at North Carolina State University under Professors Zlatko Sitar and Ramón Collazo. There he investigated the compensation of Mg-doped GaN and AlN, and this work in point defects inspired his project for the Walter Benjamin Fellowship. His focus here at IKZ will be to understand the correlation between impurities and UV-absorption in PVT-grown AlN-crystals, to reduce absorption in AlN crystals at wavelengths shorter than 270 nm, and thus contribute to the realization of UV-LEDs and LDs for disinfection and sterilization purposes on AlN substrates.

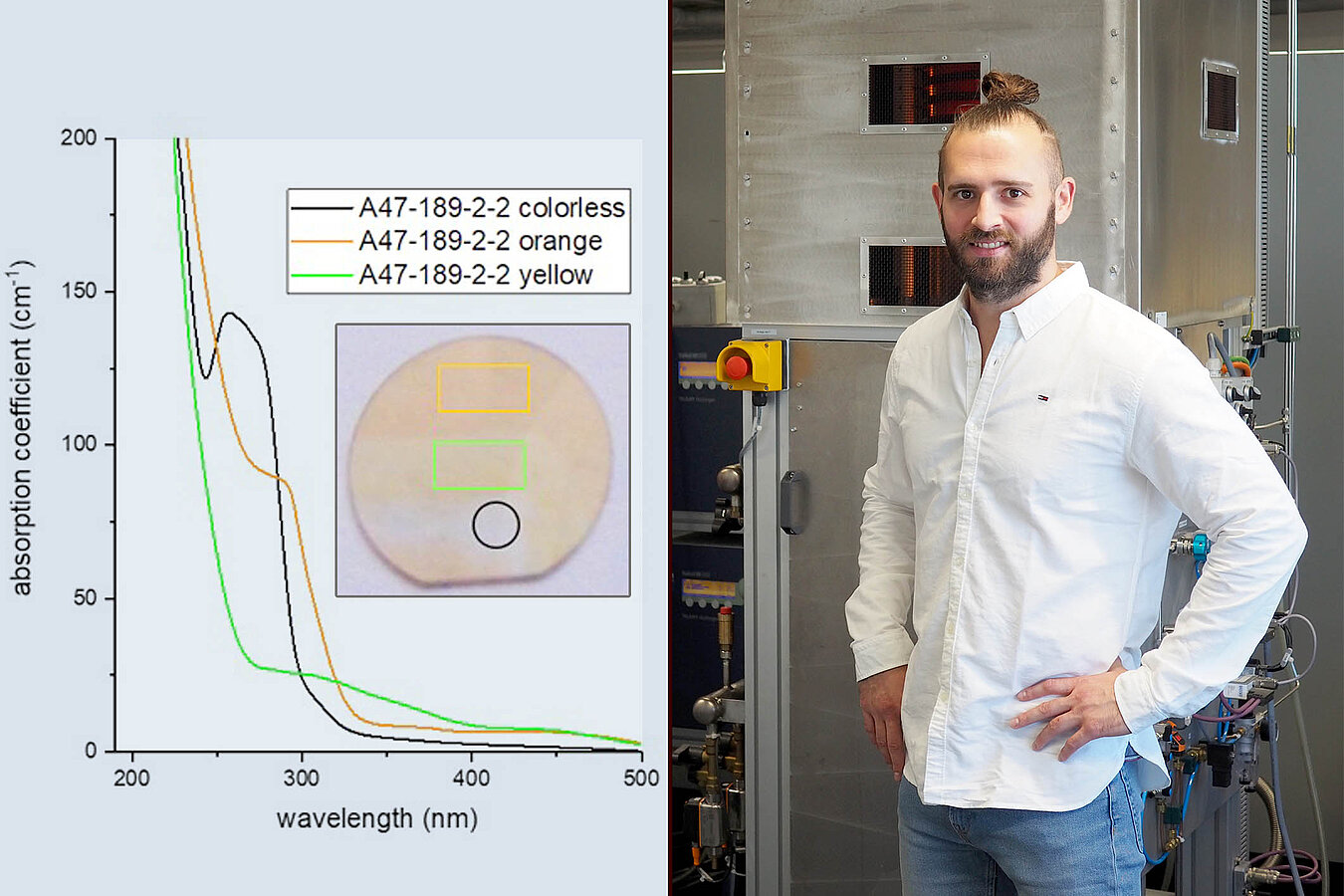

The AlN team at IKZ has previously shown that variations in the C, O, and Si of the crystal affect the ultraviolet absorption of the crystal boules. In particular, the concentration ratio of these three elements determines the intensity of the absorption peak at 265 nm and the intensity near the absorption band, especially at the wavelength of 235 nm, which is important for skin disinfection. To better understand the relationships, Andrew plans to create a tailor-made sample matrix with different impurity compositions in AlN crystals and study them using SIMS and absorption measurements.

The first prerequisite for the success of the project is to develop a method for producing AlN crystals with low impurity levels. This will primarily be achieved via purifying the source material prior to the actual growth process. Commercially available AlN powders typically contain C and O in excess of 1020 cm-3 and must undergo a pre-treatment before growth. Subsequently, technologies for homogeneous doping of the crystals with defined amounts of C, O, and Si will be developed. Since the dopant elements or their compounds have significantly different sublimation temperatures compared to AlN, the main challenge is to ensure a constant dopant concentration in the growth space throughout the AlN growth. To date, no work on in situ doping during PVT growth of AlN crystals is known from the literature. Finally, the results SIMS and absorption measurements of the samples with different impurity compositions will be used, among other things, to train an AI algorithm to identify the impurity content of a crystal without the need for further SIMS analysis.

Further information:

Thomas Straubinger | Aluminium Nitride Crystal Growth Group