The section “Semiconductor Nanostructures” of the IKZ focusses on the task to grow thin tensile strained monoisotopic Si layers. The strain is generated by embedding the 28Si thin film within Si0.7Ge0.3 layers exhibiting a larger lattice constant. Growth by molecular beam epitaxy (MBE) takes place on strain relaxed buffer (SRB) wafers where a thick graded composition SiGe layer is grown by chemical vapour deposition (CVD) on a Si(001) wafer whereby it has to be avoided that structural defects on the surface exceed a critical density.

The materials used for the MBE grown 28Si layer have to fulfill special conditions for qubits: a high content of monoisotopic Si and Ge with even mass number to avoid nuclear noise and a very low content of impurities to avoid electrical and structural deterioration. Both requirements are necessary for stabile spin states of single electrons of the qubits.

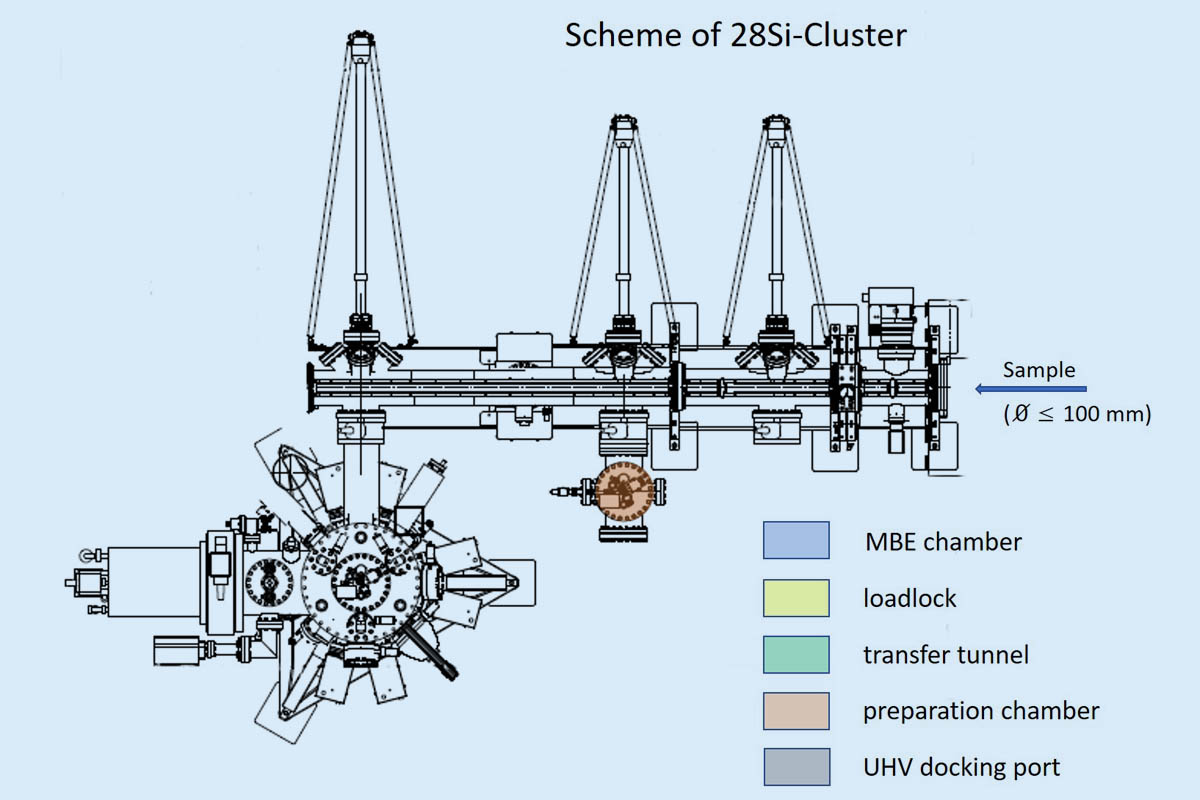

To meet these demands the use of a new, highly clean single purpose MBE device has been already fixed during the conceptual phase of the project “SiGeQuant”. Only the isotope enriched materials shall be used in this facility. Now, the new MBE called “28Si-Cluster” is finally designed and will be produced by the Dr. Eberl MBE-Komponenten GmbH. The long-standing competence of this company in configuring MBE devices for Si films in general and films for high-electron-mobility transistors with similar low impurity requirements in particular is very helpful.

The Figure shows the composition of the 28Si-Cluster. The strain released buffer wafer will be inserted from the right side to the load lock onto a trolley. Then, it can be moved under ultra-high vacuum (UHV) conditions to the preparation chamber used for outgassing the wafer and to the MBE chamber. There, a vacuum in the low 10-11 mbar range or better (XUHV) is planned. Both the liquid nitrogen cooling of the chamber wall by a shroud and the liquid helium driven cryo-pump account to realize XUHV. The high-end quadrupole mass spectrometer with an QMA 400 analyzer allows to detect very fast partial pressures of 10-15 mbar up to a mass number of 512 at very low outgassing rates during operation. So, we should be able to find minor sources of impurities during the MBE process.

The monoisotopic material for the Si and Ge evaporators will be prepared by our Russian cooperation partners and by colleagues of the IKZ section “Semiconductors”.

Further information: Yujia Liu, Thomas Teubner and Torsten Boeck