In the past, the process development and optimization were based on general learning through experience that is rather speculative when applied at the industrial scale or for growing new materials. Nowadays, global numerical CFD simulations combined with model experiments on a small scale and close-to-real experiments on pre-industrial scale have helped understanding the crucial process steps and factors determining the crystal growth, but seriously increase the developing time and costs for the new technology [1]. In consequence, it took e.g. ca. 40 years to enlarge Si wafers diameter from 1 inch to 12 inch.

One of the most powerful innovative tools that appear in the field of crystal growth in the last decade is machine learning. This collection of statistical methods has a great potential in acceleration of fundamental and applied research, particularly with respect of process and equipment optimization, process control and interpretability of the results. Nowadays, we are witnessing an explosion of the applications in all fields of crystal growth and on all scales, from bulk to epitaxial growth, from numerical simulations to experiments and from atomic to macro scale.

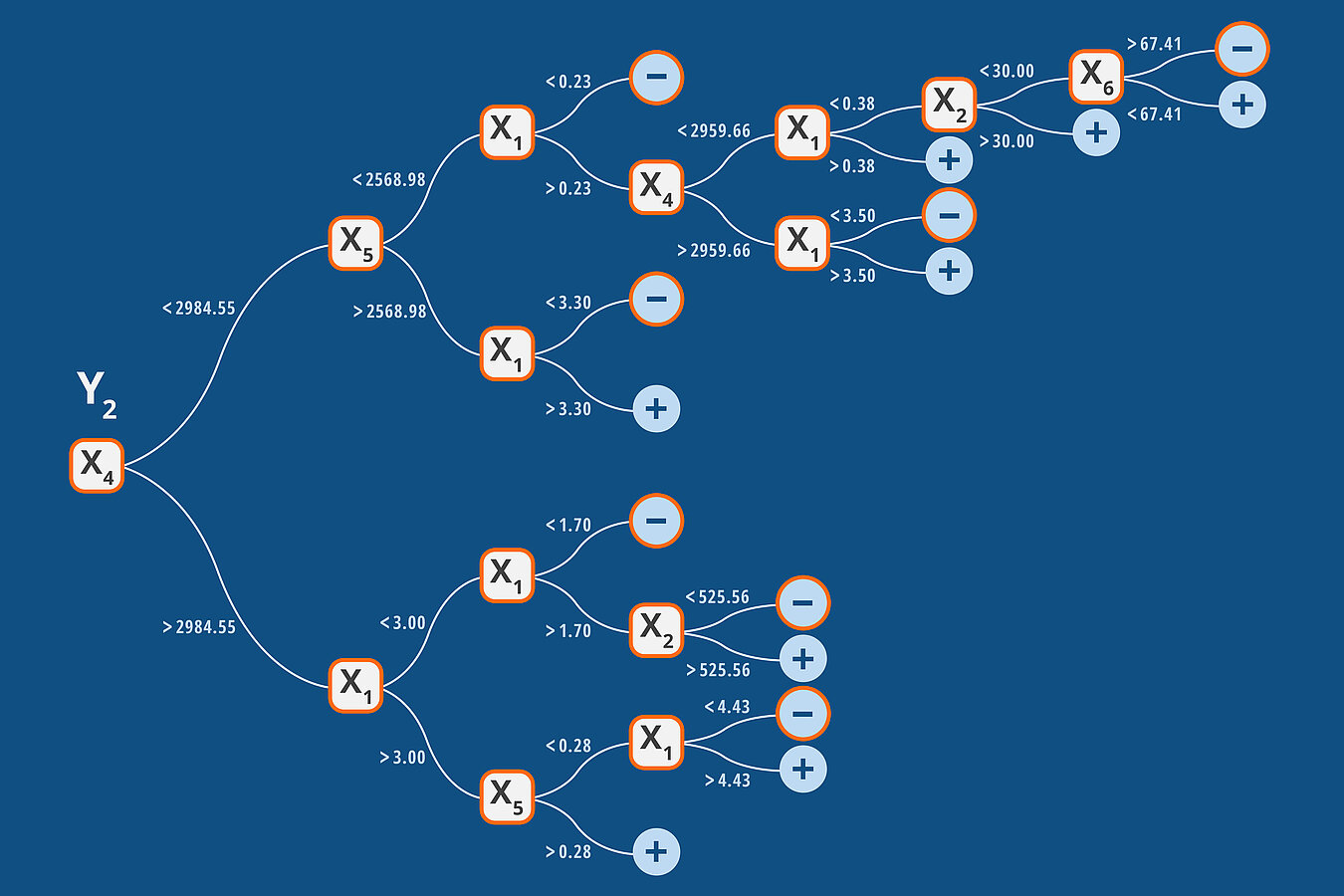

Numerical modelling group started activities in this field 5 years ago in cooperation with the Technical University Dresden and the Leibniz Institute for Catalysis (LIKAT), therewith belonging to pioneers in the bulk crystal growth. In the frame of two projects granted by DFG, machine learning techniques have been and still are used in the process control and the development of crystal growth furnaces and processes.

Success of machine learning is strongly related with the volume and quality of training data, therefore data collection and analysis is a key pillar for the success. In view of this, numerical modelling group is actively participating in the generation of the national data infrastructure in the field of material science in the frame of FAIRMAT project [2] as a task leader for the topic ´Synthesis from the melt´.

This group is also promoting the machine learning techniques in the German, European and International Crystal Growth Societies and during conferences, e.g. as a member of the BR 50 interest group “Artificial Intelligence”, as a chair of the session “Digitalization in crystal growth” in ECCG7 Paris 2022 and as an invited lecturer on DKT, ACCGE-22, IWCGT-8 and JCCG-49 [3-6].

[1] N. Dropka, M. Holena, Application of Artificial Neural Networks in Crystal Growth of Electronic and Opto-Electronic Materials, Crystals 10 (2020) 00663.

[2] FAIRMAT, https://www.fair-di.eu/fairmat/fairmat_/consortium

[3] N. Dropka, M. Holena, Recent advances and applications of data mining and machine learning in bulk crystal growth, DKT-2021, Berlin (2021/10/6-2021/10/8)

[4] N. Dropka, K. Böttcher, M. Holena, Smart development of vertical gradient freeze crystal growth recipes, ACCGE-22, USA(2021/8/2-2021/8/4) Virtual Conf.

[5] N. Dropka, M. Holena, Can artificial intelligence help us make better crystals? IWCGT-8,Berlin (22/05/29-22/06/02).

[6] N. Dropka, S. Ecklebe, M. Holena, Towards fast prediction of VGF growth process by recurrent neural networks, JCCG-49, Japan (2020/11/09-2020/11/11) Virtual Conf.

[7] N. Dropka, K. Böttcher, M. Holena, Development and optimization of VGF-GaAs crystal growth process using data mining and machine learning techniques, Crystals 11 (2021) 1218.