IKZ is a member in the international LEGEND project [1] where not natural but even enriched 76Ge detector crystals are needed to make progress on our understanding of the very fundamentals of the Universe.

The CZ-IV working group of the Semiconductors section is specialized in the growth of large diameter Germanium (Ge) single crystals with a low defect density, along with zone-refining Ge bars up to ultra-high purity.

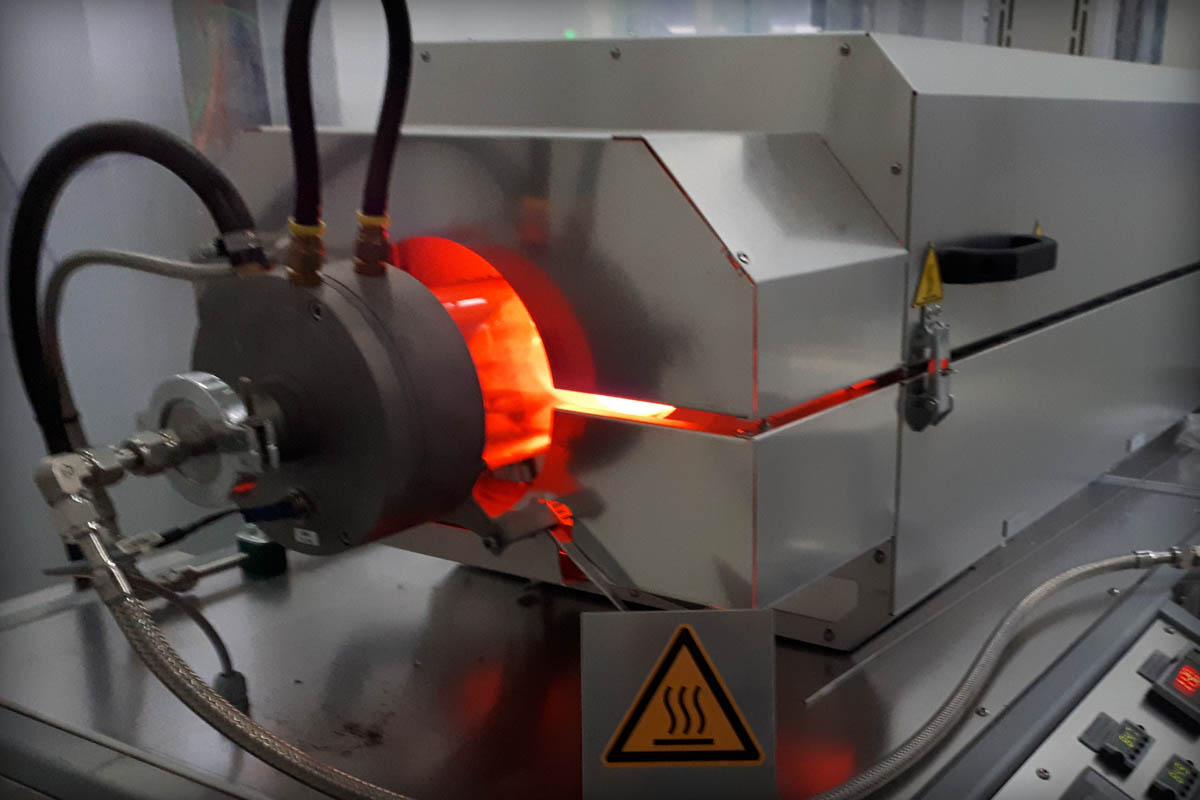

Now additionally, a new reduction furnace is set up at IKZ, which can be operated at high temperatures under H2 atmosphere. This will allow a cost reduction and a better control over the contaminations of the Ge source material for the manufacture of detectors.

Another advantage is to bring-in a full value proposition and complete production chain, starting from Germanium oxide (GeO2) toward the preparation and purification of metal bars till providing the finished high purity crystals (13 N), for e.g. detector-blocks, under one roof. In a single process, the GeO2 powder is first reduced into Ge metallic powder and then melted to prepare the Ge bars for further zone refining.

A reduction process with a very high yield of > 99% was successfully developed by our young research team of the working CZ-IV group, with a capacity of at least 1 kg Ge (and up to 2 kg GeO2) per process and as well with short reduction time (< 48 h), especially suited for materials, which require minimised cosmic ray exposure.

Isotopically-enriched 76Ge material with ultra-high purity is indispensable for the radiation detection applications (e.g. neutrinoless-ßß-decay experiments, a large and grand international collaborative effort by the LEGEND research program). Isotopically enriched Ge is provided as enriched 76GeO2 powder, which then has to be reduced to Ge bars. However, there is no optimized process readily accessible and available for realizing a very high yield reduction of 76Ge, which is an essential requirement, due to the extremely high material cost besides some special care to avoid cosmic-ray exposures.

The process was established and developed by reducing 20 kg of natural GeO2 powder. This process was then seamlessly transferred to produce 23 kg of enriched (88%) 76Ge material from oxide [2], for our co-operation partner (Technical University Munich). Afterwards, the reduced Ge bars were purified by zone refining up to intrinsic purity to be provided to the other LEGEND partners as per the requirement, for further processing and finally detector fabrication. We were able to achieve a reduction yield of 99.85% (76GeO2 in to 76Ge), which is comparable to (if not, better than) that of commercial producers. Further optimization and scaling-up to mass production could be done for ton-scale requirements of the

LEGEND experiment.

References

[1] http://legend-exp.org/

[2] K.-P. Gradwohl, J. Janicskó-Csáthy, O. Moras, S. Schönert, R. R. Sumathi, presented in LEGEND collaboration meeting, 2-6 December 2019, Seattle, USA.

More Information:

Radhakrishnan Sumathi

Section Semiconductors