Strain in crystal lattices is a measure of local or global deviations from ideal periodic atomic arrangement. These deviations typically lead to a modification of the physical properties of crystalline materials. While this effect may be detrimental in some cases, it is widely exploited in the field of strain engineering in order to optimize the material properties for a specific technological application. This concept is especially important in fields like microelectronics, optoelectronics, and photonics, where small deviations of the lattice can have significant impacts on material behavior.

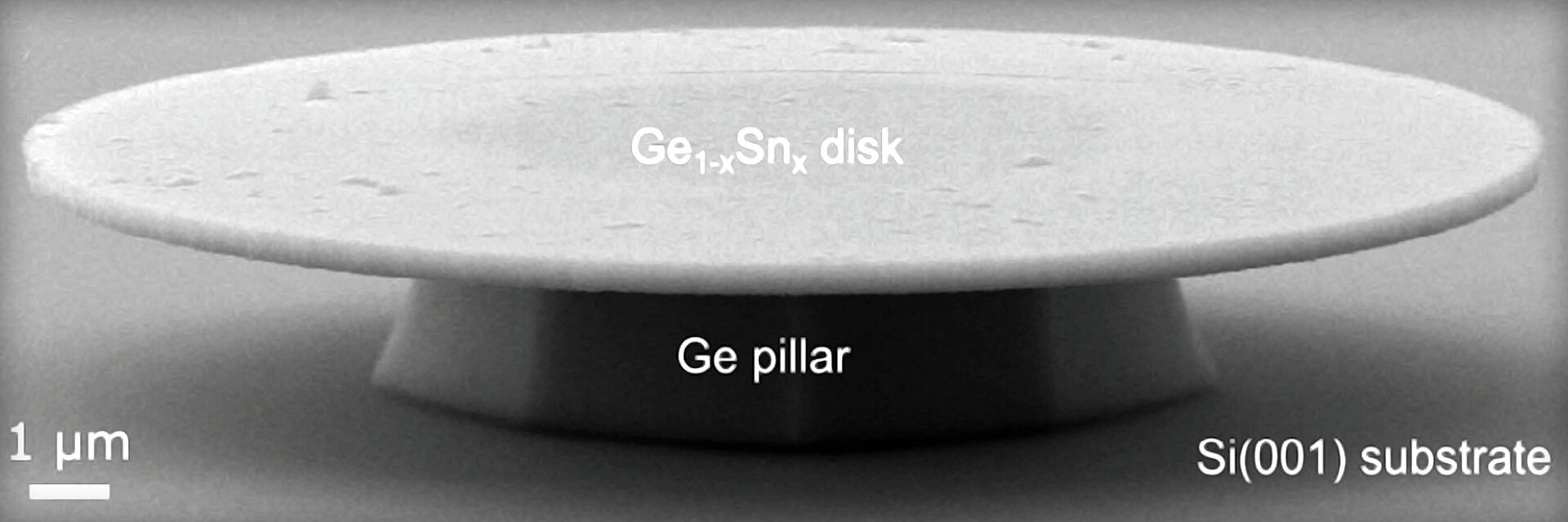

Several approaches exist in order to introduce or relax lattice strain in a functional material or device. These include alloying, growth of thick buffer layers or micro-patterning to engineer the geometrical constraints. Traditionally, however, it is challenging to understand or measure the microscopic strain distribution in patterned microstructures and most experimental methods give only access to certain components of the strain tensor. In contrast, the present study has demonstrated how 5D X‑ray diffraction microscopy provides unprecedented insights into the strain landscape within a Ge1‑xSnx/Ge micro-disk (Fig. 2) that emerges due to epitaxial mismatch, alloying and micro-patterning. The technique is based on a fine X‑ray beam focused down to a spot of approx. 50 nm, which is used to scan the sample in diffraction geometry. Based on a theoretical framework developed by IKZ scientists, the full strain tensor could be recovered by combining several of such measurements.

Ge1-xSnx alloys have tunable electronic and optical properties, making them ideal for advanced semiconductor applications. The studied Ge1-xSnx/Ge micro-disk infrared-lasing devices are based on a tin content of x ≈ 11 % and elastic strain relief by lithographic 3D patterning, which allows to shift the band-gap from indirect to direct and to increase the lasing temperature. By mapping all (shear and normal) components (Fig. 1) of lattice strain within the micro-structure, different contributions from lattice defects, alloy fluctuations and the patterning geometry could be clearly discerned. Furthermore, the high penetration of X‑rays allowed to obtain a tomographic view on different layers in the heterostructure and the obtained results have been used to benchmark current theoretical models for the prediction of lattice strain.

The experiments were carried out at the European Synchrotron (ESRF) under the leadership of IKZ and in collaboration with partners from IHP – Leibniz Institute for Innovations for High Performance Microelectronics in Frankfurt (Oder), RWTH Aachen, University of Milano-Bicocca, Forschungszentrum Jülich and the CNR Institute for Microelectronics and Microsystems, Italy. The demonstrated ability to map lattice strain in 3D microstructures with both high precision and high spatial resolution opens up new ways for tailoring material properties at the nanoscale, which can eventually lead to the development of more efficient electronic and optoelectronic devices.

![[Translate to English:]](/fileadmin/user_upload/News/24_09_News_GeSn.jpg)